|

East Kelly Avenue- Jackson Town Green Features

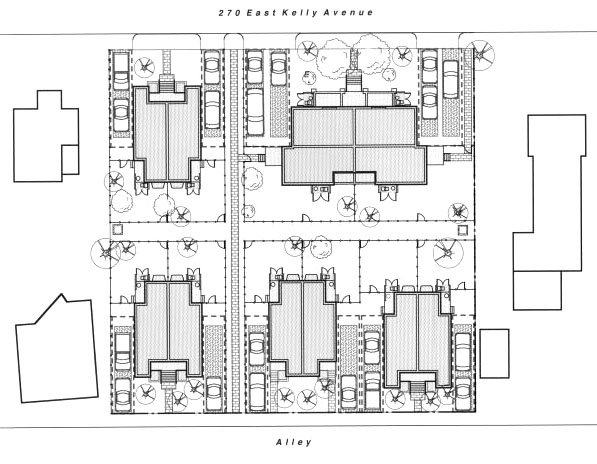

As in numerous communities, housing costs in Jackson Hole, Wyoming are beyond the reach of many of the area’s workforce. The Jackson Hole Community Housing Trust responds to this need by subsidizing the development of deed restricted housing for the families and individuals who contribute to and diversify their populace. The residents served by the Housing Trust would not be able to remain a part of the community without projects such as the East Kelly Avenue Housing which provides 28 affordable units. The project is built on two

nearby sites on East Kelly Avenue in the heart of an established residential

neighborhood within the town of Jackson. Its vernacular celebrates the mixed

scale neighborhoods and development patterns historically found in mountain

towns of the Rocky Mountain West. One fourplex and four duplex units designed

to resemble larger single family homes are built on the site closer to the center

of town. On the same street towards the edge of town the units are single family

detached homes and duplexes. All the units are of modular construction.

Great care was taken to positively impact community attitudes toward affordable housing, increased density and modular construction - not only by drawing on the context of Jackson’s older housing stock but also through intelligent and respectful site planning. Half the units face mid block alleys, treating them as interior streetscapes in a gesture towards the future development of Jackson. All units incorporate front porches and public mid block walkways connecting street and alley to encourage walking, cycling and interaction between residents and neighbors. Backyards are generously landscaped and treated as unfenced courtyards. The sites were selected primarily because of their “in town” location, close to established businesses, public transportation, and bicycle routes. The 270 project, called Arbor Place, replaced a large parking lot and three accessory structures with 12 affordable homes. Existing trees and plantings were preserved and incorporated into Arbor Place. The 565 project, named 12 Pines, replaced a single home and rental trailer with 16 affordable homes painstakingly inserted between several existing trees and accessible to a large public park via the alley. The majority of units at 12 Pines are single-family detached homes for families with children.

To make the project financially feasible

and provide the community with an example of urban density in excess of the town’s current

regulations but in line with Jackson’s “Town as Heart” initiative, a year long F.A.R. bonus

had to be enacted for all 100% deed restricted housing projects along with a reduction of

the parking spaces required. The project serves the community by setting a positive example

for future homeowners and developers of just how attractive and comfortable modestly sized

units can be, that density concentrations within established town boundaries are to be

embraced not avoided, and that modular construction techniques can result in high quality

projects indistinguishable from less efficient construction methodologies.

The modular construction facility receives building materials in bulk by rail, and is located approximately 120 miles from Jackson. By Wyoming standards that’s local, reducing embodied energy. During fabrication, construction materials were used to maximum efficiency and waste was recycled directly by the modular fabricator. Prefabricated floor trusses used to accommodate clear spans and ductwork have the added benefit of using smaller members harvested from younger trees. Painted MDF trim, laminate floor and cabinetry feature particleboard substrates produced from sawmill waste products. At the job site, a separate dumpster for wood products was maintained, and taken to the local recycling center. To encourage continued recycling, each housing unit has a dedicated cabinet for small recycling bins in the kitchen and an enclosed exterior storage compartment integrated into the rear porch for both recycling and trash stockpiling. To minimize water waste, an automatic sprinkler system timed to minimize surface evaporation maintains the landscaping.

Lessons Learned from the Architect: Be sure to do your homework if you plan to suggest a technology or material people aren’t familiar with. If you come to the table knowing what it will cost, where to get it and how it benefits the project you’ll have a much greater chance of success.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||

Modular construction

was used because of construction costs and staging constraints. This approach, along with the

repetitive nature of the unit layouts, allowed for a high level of quality control and early

troubleshooting of problems. These efficiencies allowed the specification of durable, low

maintenance finishes and period details such as laminate flooring, hardwood stair treads, deep

windowsills, period casing and handrails. Exterior finishes include fibercement siding and trim,

divided light vinyl windows, exposed rafter tails and split faced concrete block lightwell

enclosures.

Modular construction

was used because of construction costs and staging constraints. This approach, along with the

repetitive nature of the unit layouts, allowed for a high level of quality control and early

troubleshooting of problems. These efficiencies allowed the specification of durable, low

maintenance finishes and period details such as laminate flooring, hardwood stair treads, deep

windowsills, period casing and handrails. Exterior finishes include fibercement siding and trim,

divided light vinyl windows, exposed rafter tails and split faced concrete block lightwell

enclosures.  For improved Indoor Air

Quality (IAQ), the modular building components were stockpiled at the fabrication facility for

four months prior to delivery, giving construction materials time to offgas. To avoid moisture

issues that can contribute to IAQ problems, exterior walls were designed to minimize condensation

and to dry to the exterior. Features that make the envelope more energy efficient include double

glazed windows, insulated floor trusses to minimize ductwork heat loss and dropped ceilings at

bathrooms for an unbroken insulation layer above the exhaust ductwork. Forced air heat and domestic

hot water are delivered via a natural gas fired furnace and water heater. The Jackson Hole climate

does not require supplemental cooling.

For improved Indoor Air

Quality (IAQ), the modular building components were stockpiled at the fabrication facility for

four months prior to delivery, giving construction materials time to offgas. To avoid moisture

issues that can contribute to IAQ problems, exterior walls were designed to minimize condensation

and to dry to the exterior. Features that make the envelope more energy efficient include double

glazed windows, insulated floor trusses to minimize ductwork heat loss and dropped ceilings at

bathrooms for an unbroken insulation layer above the exhaust ductwork. Forced air heat and domestic

hot water are delivered via a natural gas fired furnace and water heater. The Jackson Hole climate

does not require supplemental cooling.