| Project Summary: Little Ajax Affordable Housing

OWNER/DEVELOPER

Peter L. Gluck and Partners and Aspen GK III, LLC

ARCHITECT

Peter L. Gluck and Partners, Architects

LANDSCAPE ARCHITECT

Peter L. Gluck and Partners, Architects

CONTRACTOR

GK Construction LLC

| FUNDERS: |

TYPE: |

| City of Aspen |

$4.924 million subsidy |

DEVELOPMENT TYPE:

Affordable housing on brownfield site.

DENSITY: 14 units/acre

DEVELOPMENT PROFILE

| Type |

#/Units |

Size (sf) |

| 2 BR |

1 |

925 |

| 3 BR |

13 |

1200 |

| Total |

14 |

|

Laundry: all units are equipped with individual laundry hook up.

Courtyard/play: open space + public trail connections

Parking: 23 covered spaces + 2 guest spaces

Total site area: .5 acre + .5 acre open space |

DEVELOPMENT COSTS:

Land cost: $1,950,000; Constr. costs: $4,000,000; Completed in October 2006.

|

|

|

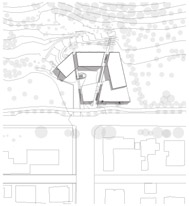

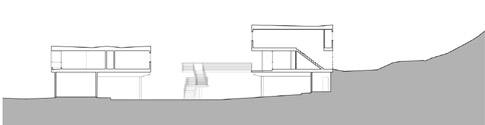

Little Ajax is situated between an established neighborhood and mountains. The project consists of 14 communally-oriented affordable family units. A skewed geometry allows the building to conform to the streetscape in front and the natural contours and vegetation of the slope above. A logical transition is thus created between the street grid of the city and the irregularity of the mountain landscape into which it terminates. The design integrates a dense program into a residential neighborhood by breaking the scale down into five "house-scale" elements. Uses of color and form create a modern insertion into a neighborhood with a mix of architectural styles.

Gluck and Partners acted as both architect and contractor with a great deal of community input and a subsidy from the city of Aspen. Previous mining activity on the site left a brownfield that was remediated through a voluntary state program. The site was very difficult, nearly unusable because of brownfield issues and a steep slope. Community opposition to affordable housing built within the Aspen city limits was also present. This was overcome through some concessions, including the elimination of the market-rate component of the project which allowed for increased open space and decreased density.

The design depends upon three angled “slots” that slice through the projects' site, breaking it down into an interconnected series of buildings containing between 1 and 6 units. Because the "slots"

divide the building into smaller elements, nine of the fourteen units have a corner location with multiple view corridors and natural cross ventilation. Two public trail connections, located separate from the parking area, were also created through this skewed courtyard geometry. A series of second floor walkways are punctuated by playful bridges and lookouts and provide multiple connections to the units. Multiple circulation routes augment fire safety and provide privacy by insuring that most units are accessed without having to pass by neighboring apartments. Tuck under parking also reduces the building footprints while creating private house-like units. Parking fees are an incentive for residents to reduce the number of vehicles per person, which is possible as Little Ajax is highly accessible to pedestrians and cyclists. Covered bike storage is located near units, and in addition to the public trail connections, the project is within one block of local bus lines.

|

|

Dedicated open spaces have been created with low-maintenance natural plants. Natural grasses and wildflowers act as drought-resistant landscaping, while all stormwater is kept on-site using dry wells. Dual flush toilets were also installed in the units.

The building was designed to exceed the energy code by 15%. Compact fluorescent and fluorescent lighting was used in units and public lighting is controlled by motion sensors. Continuous window walls create a high degree of daylighting. All units are served by a centralized hot water heating system, highly efficient boilers with outdoor resets, and mechanical ventilation.

Notable materials used at Little Ajax include heavy gauge corrugated metal, cement board, bamboo floors, finger-jointed studs, recycled content carpet and blown in cellulose insulation. Engineered lumber was used for some floors as well as the roof, which is ventilated and has a high solar reflectance index. Indoor air quality was a concern; the architects specified low-VOC paints and finishes, pre-finished floors, and mechanical ventilation to bring in fresh air. Moisture is managed through rain screens and an air space between the exterior envelope and waterproofing. No air conditioning systems were installed. During construction, cardboard, paper, metal and wood were recycled. Post-construction, trash compactors reduced trips to the trash room and the number of pick-ups required by the trash company. The large trash room accommodates multiple bins for recycling which are built into the cabinetry in the units.

To help ensure that the units remain healthy and energy-efficient, the architect provided detailed operating manuals for all building occupants. They also aided in securing building maintenance contracts with the mechanical subcontractor.

Lessons Learned from the Architect

- Being both contractor and architect was helpful to the project because green materials or systems are not necessarily more expensive, but they often require increased planning and organization which the architect was able to provide without hiring an outside contractor. Also, some systems, such as the super-insulated building envelope with a passive ventilation system, would have been difficult to get many outside contractors to do.

- Bamboo flooring was a new material for the architect, and they were told "miracle stories" about how well it would work, even on a slab on grade. The architect argues that bamboo behaves like any other wood on grade and can shift when installed.

- Frost Protected Shallow Foundations - In Aspen, the frost line is at 4 feet below grade. The architect wanted to use a FPSF but because of scheduling could not make the pour until November. This was too late and would have resulted in the pour sitting on top of frozen ground and becoming damaged. In the end, a hybrid system that combined elements of shallow and deep foundations was used that was shallow and which still avoided the need for deep trenching.

Jury Comments

- Well executed project with appealing contemporary design-works well given the adjacency to the mountains

- Strong design for affordable housing

- These homes are elegant and airy with strong connections to the landscape

AIA Green Housing Guidelines

|

Little Ajax Affordable Housing

|

1

|

Community Context |

Infill/ brownfield/adaptive re-use/high density |

Previous silver mining in the late 1900s left a brownfield site that was remediated through a voluntary state program. The project is a moderate to high density development within 5 blocks of multiple community and township services.

|

| Locate near public transportation |

Within one block of public buses; 2nd floor walkways provide connections to public bike and walking trails.

|

2 |

Site Design |

Pedestrian/bicycle friendly |

Site incorporates 2 public trail easements that connect into the city trail system and tie directly in to building circulation spines, covered bike storage near units and close to public trail points.

|

3 |

Building Design |

Daylighting |

Continuous window walls and alignment with public spaces create a high degree of interior daylighting. |

| Green roofs/cool roofs |

High solar reflectance index roof. |

| High Performance Building Envelope |

Walls have an R value of 19, roof has an R value of 49 and slab has an R value of 10. Window frame material is thermally broken aluminum storefront - glass is 1" insulated unit with low-E coatings intermixed with 3.5" insulated panels custom integrated into storefront system. Moisture management through rain screens and air space between exterior envelope and waterproofing; ventilated roofing system. |

4

|

Water Conservation and Management |

Stormwater Management |

All stormwater is kept on-site using native plants in vegetated swales and drywells. Natural grasses and wildflowers act as drought-resistant landscaping with temporary irrigation system only.

|

| Water Saving Appliances |

Dual flush toilets.

|

5

|

Energy Efficiency |

Energy Efficiency Heating and Cooling |

Natural cross ventilation with windows on multiple exposures. Ducted system brings fresh air into space and expels air using timed exhaust fans. Building designed 15% over the required energy code. Centralized hot water heating. Heating plants with outdoor resets. Highly efficient boilers super-insulated with mechanic ventilation. No air-conditioning systems.

|

| Energy Star Appliances/Lighting |

Energy Star appliances used. Compact fluorescent and fluorescent lighting. Public lighting on motion sensors.

|

7 |

Recycling |

Recycled Content Materials or Recycling On Site |

Recycled content carpeting, insulation, and concrete. During construction, cardboard, paper, metal and wood were recycled. Large trash room accomodates multiple bins for recycling which are built into the cabinetry.

|

8 |

IEQ |

Limit Emissions/moisture/sound/allergens |

Low-VOC paints and finishes. Pre-finished floors.

|

|