IE 455 Robotics & Programmable

Logic Controllers

Abstract & Laboratory Experiments

Prerequisites: junior/senior standing or see Professor McDermott for permission

Fall Semester

Introduction to the design and implementation of programmable logic controllers for use in industry in the areas of automotive assembly, pharmaceutical manufacturing and chemical processing. Topics include ladder logic, input/output ports, continuous process control, timing and counting functions, and digital gate logic.

Mitsubishi Medoc PLC IDEC WindLDR PLC DirectLogic 14IO PLC

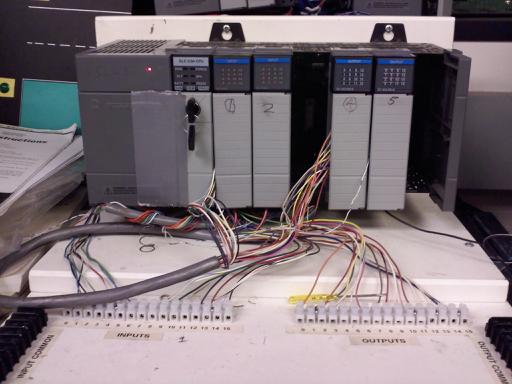

AllenBradley SLC5/04 PLC

Typical PLC Topics

Spray painting workcell

Spot welding workcell

Traffic light system

Elevator system

Home/car alarm system

Conveyor system

Laboratory Experiment # 1

Design and develop a PLC system to achieve the following requirements:

5 input ports or more

2 output ports or more

Ladder logic programming

Logical AND gate

Logical OR gate

Students will work in teams.

The laboratory experiment will be presented in class in two weeks.

Each team will prepare a concise team report on the experiment.

PLC System Procedure

1 Select process

2 List steps in process

3 Define Input and Output ports

4 Program computer using Ladder Logic

5 Download program to PLC

6 Test PLC operation

7 Wire Input and Output ports

8 Demonstrate PLC operation

9 Develop Team Report and/or PLC improvements

Laboratory Experiment # 2

Þ Design and develop a PLC conveyor system to achieve the following requirements:

® conveyor S1 activates assembly station WS1

® conveyors WS2,WS3&WS4 activates three welding stations in parallel

® conveyor 5 activates inspection station 5

The output of conveyor 1 activates all three welding stations in parallel. When the welds are completed,manual switches are triggered to show that each welding process is completed. A delay could also be built in to simulate the welding processes.Next the inspection station is triggered and separate outputs indicate good welds or defective welds.

Þ Students will work in teams

Þ The laboratory experiment will be presented in class in two weeks.

Þ Each team will prepare a concise team report on the experiment.

Laboratory Experiment # 3 Mod 1

Develop in the PLC software a ladder logic diagram that emulates the Paint Spraying Process in an automobile assembly plant.

Use a conveyor system to transport the vehicle ,and three paint spraying robots to emulate the painting process

Download the ladder logic to the PLC

Wire in the input and output devices

Check the wiring

Show the operation of the paint spraying process as it is controlled by the PLC

Use counters to determine the number of vehicles painted and timers to simulate the three different painting robots