Micro and Nano Mechanics Laboratory

------------------------------------------

Newark College of

Engineering

|

Micro and Nano Mechanics Laboratory

------------------------------------------

Newark College of

Engineering

|

|

|

|

Mechanics of Energy Storage

Materials

In spite of decades of research, the capacity of the state-of-the-art Li-ion batteries (which, for example, directly effects the range of an electric car) did not improve to meet the future energy storage demands . Replacing the existing electrodes with high performance materials such as Si and Ge (as anodes) can improve the capacity of lithium-ion batteries by 35%, which is a remarkable increase. However, these high performance materials exhibit poor cyclic performance (i.e., rapid degradation) due to stresses generated in these materials during charge/discharge (or lithiation/delithiation) reactions. The mechanical stresses not only cause fracture of electrodes but also contribute to chemical degradation (i.e., SEI layer), transport properties of electrodes, and kinetics of chemical reactions. The stresses play a key role in the performance of cathode materials as well. Hence, it is essential to understand the mechanical behavior of electrodes and how this effects the transport and kinetic properties. Motivated by such practical problems, we have been developing in situ experimental techniques and multi-scale theoretical models to provide a better understanding of the chemo-mechanics of battery electrodes at various length and time scales. For example, we recently demostrated that Ge electrode when lithiated undergoes extensive plastic doformnation which could potentially contributes to battery losses. Also, we found out that the PVdF (the polymer binder in batteries) behaves as an elastic-viscoplastic material which will influence the degradatoin behavior of composite electrodes. Please click the publicatios link for full list of topics we have looked at sofar.  Degradation (or cracking) of Si thin film electrode (S.P.V. Nadimpalli et al. JES 2013) after several charge/discharge cycles

The

global additive manufacturing market for both rapid prototypes and

functional end-use parts is expected to grow at a compound annual

growth rate of 20%. Such a rapid market growth is realized due to the

advantages such as design flexibility, customized geometries and low

volume production, short design-to-manufacture cycle times, and reduced

assembly time. These advantages make 3D printing as the new

manufacturing paradigm. A recent sustainability perspective reveals

that 3D printing has the potential to reduce costs by US$170-593

billion, the total primary energy supply by 2.54–9.30 EJ and

CO2 emissions by 130.5–525.5 Mt by 2025. Additive

manufacturing has been successfully adapted in several industries

including medical, aerospace, automotive, machinery, and architecture

industries. Due to the vast and promising applications of FDM printed

parts, their mechanical performance has been the focus of many studies.

However, the fracture properties of the 3D printed thermoplastics has

not been studied before. Here we developed fracture mechanics-based

methods to evaluate the fracture behaivor of 3D printed thermoplastics.

This work is a collaborative effort between our group and Prof. Ameli's

group at University of Washinton Tri-Cities.

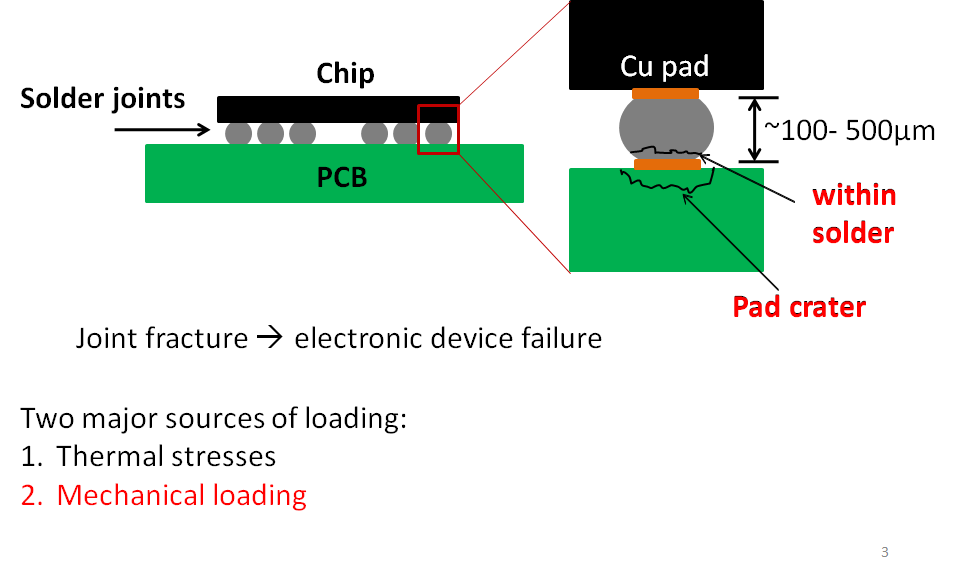

Microelectronic packages experience various thermal and mechanical

loading conditions during their assembly, testing and service

phases. Although most research has focused on solder joint failure due

to thermal fatigue, the mechanical strength of solder joints is also an

important performance parameter in many devices. This is especially

true in higher density array packages, larger printed circuit boards,

and electronic devices for aerospace and automotive applications, where

mechanical loads can be a significant cause of failure during service

and assembly. One of the main causes of device failure is the

fracture of solder joints in these packages. However, the

fundamental fracture behaviro of lead-free solder joints is not

understood thoroughly. We have developed experimental techniques

to characterize the fracture behavior of lead-free solder joints.

|

| MNM Lab, Prof. Siva Nadimpalli, Office: 973 596 3678, Lab: 973 596 5667, Email: nadimpal@njit.edu |