|

The

purpose of this project is developing and delivering clean

renewable energy to homes and business in collaboration with

Cattron, Stanley Vidmar, Bolaball and

I.D. Systems, INC. Bio-Green

Alternative Energy Solutions is

intended to replace fuel sources without the undesired

consequences of the fuels.

Our company’s mission is

bringing innovative ways to cover the need to overcome the

shortage in energy by developing secure energy solutions that

are sustainable and are technologically and financially viable.

Our

experience in industry gives us a deep insight into the

technical, policy, economic, and regulatory challenges being

faced by our energy clients. We help clients view energy issues

in a broader context, and to manage energy strategically to

ensure that their clean energy and energy reduction solutions

grow with the organization.

For many

years mankind has been looking for an alternative source of

electrical power. Presently, high oil prices make the

investment for this new alternative viable. This is needed to

solve the continuing pollution resulting from burning fossil

fuels and from nuclear waste.

In order

to monitor and control the wind percentage in turbines and

reduce its power consumption Bio-Green Alternative Energy implements controls to achieve

maximum performance in manufacture and installation of superior

quality wind turbines by using control charts for variables and

attributes. These charts are one of the most useful tools when

studying variation. They offer a method that determines whether

a process is stable or unstable which enables the user to modify

when unstable or control the process if already stable. This can

be accomplished by sampling of a particular process, analyzing

the results; assign a cause and taking any needed actions.

The

turbines are designed for maximum durability in sustained high

wind environments with multi-voltage controller is included and

excess power is diverted through a resistor network that can

also be used for area heating.

(SPC) is

an effective method of monitoring a process through the use of

control charts. Control charts enable the use of objective

criteria for distinguishing background variation from events of

significance based on statistical techniques. Much of its power

lies in the ability to monitor both process center and its

variation about that center. By collecting data from samples at

various points within the process, variations in the process

that may affect the quality of the end product or service can be

detected and corrected, thus reducing waste as well as the

likelihood that problems will be passed on to the customer. With

its emphasis on early detection and prevention of problems, SPC

has a distinct advantage over quality methods, such as

inspection, that apply resources on detecting and correcting

problems at the end product or service one.

In addition to reducing waste, SPC can lead to a reduction in

the time required to produce the product or service from end to

end. This is partially due to a diminished likelihood that the

final product will have to be reworked, but it may also result

from using SPC data to identify bottlenecks, wait times, and

other sources of delays within the process. Process cycle time

reductions coupled with improvements in yield have made SPC a

valuable tool from both a cost reduction and a customer

satisfaction standpoint two.

Collaborating Companies

1.

Stanley Vidmar Tough Storage Solutions:

2.

Bolaball INC:

3.

Cattron

Group International:

4. ID Systems INC:

Control

charts for variable were developed by Dr. Walter A. Shewhart

while working for Bell Telephone labs in 1920’s. These Variable

Control Charts is a statistical tool to determine if a process

is in control that deal with items that can be measured, such as

height, weight, speed, and volume. The reasons for using control

charts, is because it improves productivity, make defect

visible, determines what process adjustments need to be made,

and determines if process is in or out control. To calculate the

major lines in a control chart, we can:

|

Take the

average value by taking the average of the sample data,

|

|

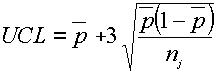

UCL: Multiply

the standard deviation by three, and then add the value to the

average value |

|

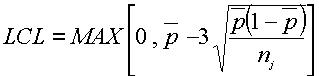

LCL: Multiply

the standard deviation by three and then subtract that value

from the average value. |

UCL,

LCL (Upper and Lower Control Limit)

X-bar Chart:

1. Lower

Control Limit:

Mean –

3*sigma

n(1/2)

2. Center

Line:

Process mean

3. Upper

Control Limit:

Mean +

3*sigma

n(1/2)

R chart:

Lower Control Limit:

R-Bar – 3*d3*sigma

Center Line:

R-Bar

Upper Control Limit:

R-Bar + 3*d3*sigma

Here is how we

can interpret the data. First, the study always starts with the

R-chart (bottom right hand corner of the excel document). If the

R-chart shows a process in control, then the X bar chart can be

analyzed, but not before. There are typically two conditions to

check the status.

Condition 1

-

There are out of control upper and lower limits. If they are not

exceeded, then the process is in control (so far), we then check

the next condition.

Condition 2

- No

points are out of limits. Two sub-conditions have to be checked:

1. If there are

seven consecutive points above or below the central line.

2. If there are

seven consecutive points increasing or decreasing it detects

non-random patterns and shows that the process is out of

control.

If none of

these rules applies to the chart, then the process is still in

statistical control.

As part of our

Eco-friendly approached, our recycle process will use

microcontrollers and sensors in order to select waste plastic

material less than five pounds and more than five pounds. With

this process can select the amount of head that can be added in

the melting process.

R-Chart1

As we can see,

in the R chart, there are more than seven consecutive points

above the central line; we can call this process out-of-

control. Since the first condition was met, we can observe the

X-bar Chart

X-Bar -Chart

As we observed,

the x-Bar is in control.

After review

the R-Chart, we can see that from 2 to 9 sample number, there is

more than five consecutive points above the central line, it

means that there is a problem to detect raw material over or

less five pounds, we concluded that the process is out of

control. After we analyzed back, we investigated the process

during this period and we were able to determine the most

important reasons why the process was out-of-control;

1- The scale

that was measuring the weight of the raw material was out scale,

it means that it was off by 3 pounds. It was producing that the

scale were taking more than 2 pound raw material as a five

pounds.

2-Tthe scale

was not place on the right position. It was off by a ¾ inches.

3-Some of

sensors were cover with dust so they didn’t detect the raw

material when it was coming on the coverable belt. The sensors

could not tell the scale that a piece of material was coming and

it could not provide a valid weight.

4- Some of the

micro controllers were misaligned. The controllers did not

prevent the process to continue sorting wrong weight plastic

material.

After correct

all the problems, this is a new R-chart that we get a new

“in-control process”

R-Chart 2

Attributes are

a very important quality check as it verifies if a particular

aspect of a product is defective. If the attribute being

measured is over the certain limit (UCL) for a majority of the

samples, then the process is out of control. The attributes need

to remain between the UCL and LCL to be acceptable or in

control.

The attribute

being measured is defective buttons in the ADA (Advanced Digital

Assistant).

1. 100 Samples

are selected at random from a batch. 2. Test is performed for 20

batches. 3. The number of units with defects is recorded.

Analysis

Summary Attributes Control Chart – We tested twelve samples of

100 units. Judging from the p-chart data and u-chart data,

nothing is out of control. The average failure is 3 out of 100,

which is a 97% pass rating It indicates that the process was

under control.

However, If any

point was out of control, we would have to investigate why this

is so. Once we can assign a reason to that point, we will

identify the source of the variability and correct the situation

and repeat the sampling process to bring the process in control.

|

Total Quality Management (e-book), CIMware USA, Inc. &

CIMware Ltd. UK |

|

Research Supplements provided by Prof. Paul G. Ranky

|

|

Unique TQM e-Learning Pack, prepared by Prof. Paul G. Ranky

|

|

CIMware USA website,

http://cimwareukandusa.com |

Control Chart Templates, by Prof. Ranky

Microsoft Excel 2003

Actual spreadsheet files for control charts for variables:

These are the template file used with my own data:

|